- Products

- Thermoplastic finished parts

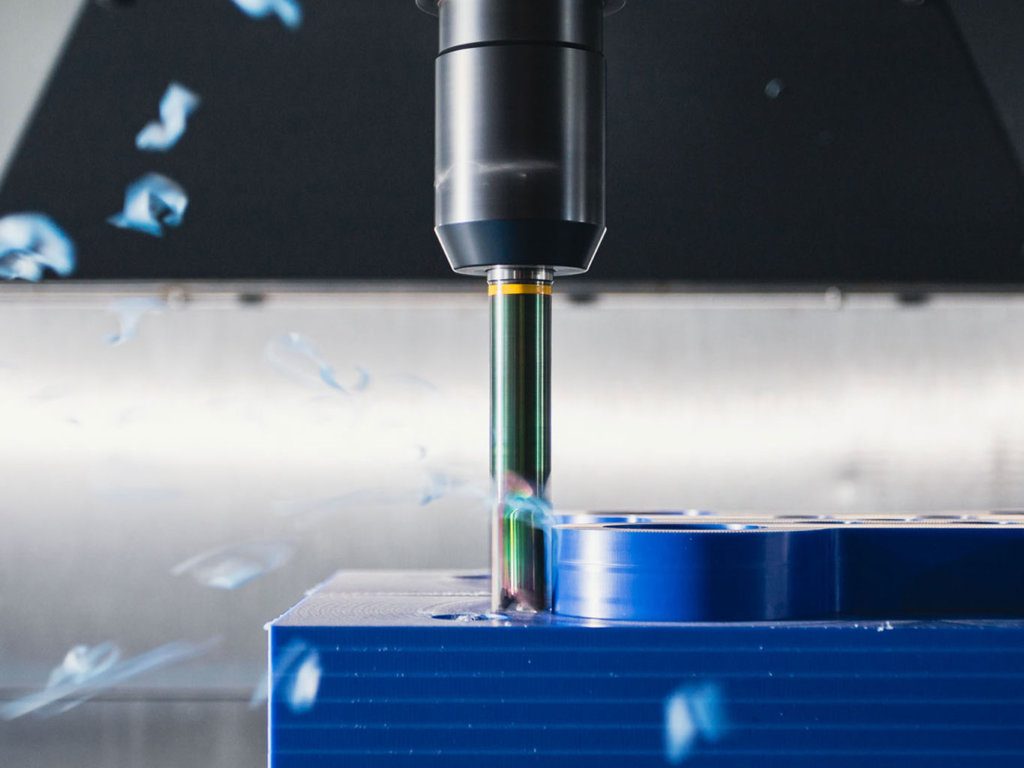

Thermoplastic finished parts

High performance thermal and electrical plastics.

Our brand Comco stands for premium thermoplastic materials of the highest quality.

We supply finished parts, semi-finished products and blanks made of premium thermoplastics. Based on their structure, thermoplastics can be divided into amorphous and semi-crystalline.

Thermoplastic finished parts materials at a glance

Comco Classic & Comco Premium

Comco-PAX, Polyamide extruded

Comco-POM-C

Comco-PAC

Comco-Powerglide, Polyamide cast

Comco-PET

Comco-PEEK

Comco-PTFE / TF

Comco-PVDF

Comco-Premium PP / PP-H

Comco-PVC-U

Comco Classic & Comco Premium

Comco Premium & Comco Classic materials based on PE-UHMW, PE-HMW & PE-HD are engineering plastics used to solve friction, wear and material flow problems in many industries. The materials of this product family are characterised by excellent sliding properties, extreme wear resistance, high impact strength as well as their very good resistance to chemicals and have become established for technical applications.

Material at a glance:

Comco-PAX, Polyamide extruded

Comco-PAX & Comco-PAC materials are universally applicable plastics for machine and plant construction. They have an optimum combination of mechanical strength, stiffness, impact resistance, sliding properties and abrasion resistance. Modifiable with many substances for application-optimised properties, Comco-PAX & Comco-PAC are ideal construction materials in mechanical engineering.

Material at a glance:

Comco-POM-C

This semi-crystalline thermoplastic features good frictional properties and high dimensional stability. POM-C offers high mechanical load-bearing capacity paired with good machinability. For all customers requiring mechanically precise components and strict tolerance ranges, our POM-C is highly recommended. Thanks to its low moisture absorption, POM-C is suitable for components that must function underwater or in a wet environment – humidity does not change its properties. POM-C is also resistant to a wide range of organic solvents and chemicals.

Material at a glance:

Comco-PAC

Comco-PAC is a universally applicable material. It is mainly used for mechanical engineering due to its high mechanical strength with sufficient toughness and very good machinability. The casting process allows a wide variety of shapes. Comco-PAC can be modified with many substances and can thus be optimised for many applications.

Material at a glance:

- Comco-PAC6 Glass / PA 6 G Glass

- Comco-PAC6 High Impact / PA 6 G High Impact

- Comco-PAC6 Wax grey / PA 6 G Wax grey

- Comco-PAC6 Heat blue / PA 6 G Heat blue

- Comco-PAC12 / PA 12 G

- Comco-PAC612 / PA 6/12 G

- Comco-PAC6 Color / PA 6 G Color

- Comco-PAC6 OL / PA 6 G OL slide modified

- Comco-PAC6 MOL anthracite / PA 6 G MOL anthracite

- Comco-PAC6 Mo black / PA 6 G Mo black

- Comco-PAC6 natural / PA 6 G natural

Comco-Powerglide, Polyamide cast

A material that keeps its promises! Our Comco-Powerglide is the top material for sliding elements of all kinds with high loads. In many technical applications, particularly good material properties are important. To achieve these, lubricant additives are integrated into the plastic matrix. The lubricant is repeatedly released at the contact surface and becomes effective. The sliding values are improved enormously without additional external lubrication and friction and wear are reduced.

Material at a glance:

Comco-PET

Alongside POM-C and PA6 casting, PET (or PET P) is one of the most widely-used technical plastics. Its excellent mechanical properties make it ideal for applications like precision mechanical components. PET offers high tensile strength and mechanical load-bearing capacity, stable hardness and good dimensional stability. Because of its low coefficient of friction, Comco PET is frequently used for components demanding high wear resistance such as wear parts, bearings, bushings, turntables or track rollers. PET is also suitable for applications in the food processing industry requiring high chemical resistance and low moisture absorption.

Material at a glance:

Comco-PEEK

PEEK offers excellent mechanical strength, high chemical and hydrolysis resistance as well as high radiation and steam resistance. The continuous operating temperature of PEEK is about 250 °C. Thanks to its excellent thermal properties, PEEK is suitable for applications at very high temperatures. Its physical properties remain unaffected by the external environment.

Material at a glance:

Comco-PTFE / TF

The plastic with the highest resistance to chemicals and extremely low adhesion, Teflon / PTFE is a soft sintered material with a low level of mechanical resistance. Its most important properties are: resistance to almost all chemicals, very high continuous service temperature, 260 °C flame retardance, low coefficient of friction, extremely low adhesion, low strength and hardness and high frictional wear.

Material at a glance:

Comco-PVDF

PVDF is a high-performance fluoropolymer known for its exceptional chemical resistance, mechanical properties, and thermal stability. Compared to other fluoropolymers, PVDF offers easier melt processing due to its relatively low melting point of around 338°F (170°C).

Material at a glance:

Comco-Premium PP / PP-H

This product family is characterised by good hardness, rigiditiy and strength as well as their excellent resistance to chemicals. The materials have proven ideal for technical applications.

Material at a glance:

Comco-PVC-U

This plasticiserfree PVC features excellent chemical resistance and good workability. Thanks to its good electrical insulating properties, high resistance to acids, alkalines and saline solutions and easy processing, PVC has proven itself in the chemical industry. It is well established as a common material in container and plant construction, the electrical industry and the construction industry. Our PVC is free of DOTE, lead, cadmium, CFC, silicone, PCB, bisphenol A, plasticisers and heavy metals.

Material at a glance: