- Products

- Thermoplastic semi-finished products

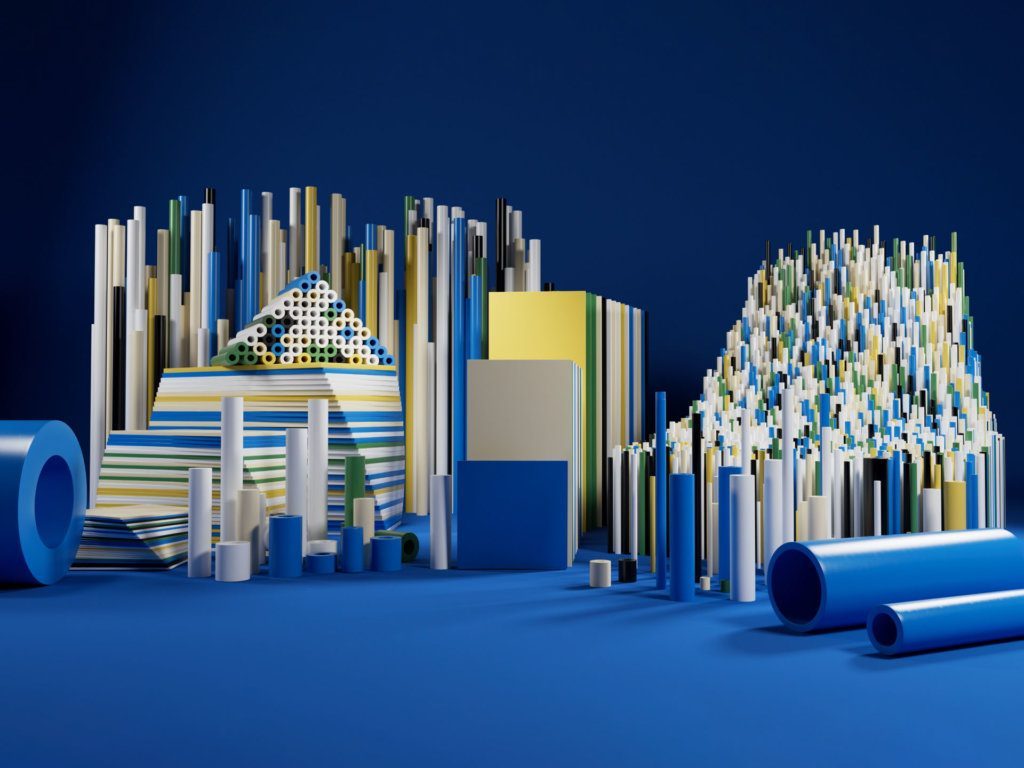

Thermoplastic semi-finished products

Premium materials of the highest quality

Our brand Comco stands for premium thermoplastic materials of the highest quality.

We supply finished parts, semi-finished products and blanks made of premium thermoplastics. Based on their structure, thermoplastics can be divided into amorphous and semi-crystalline.

Thermoplastic semi-finished materials at a glance

Comco-PA 6 C

Comco-POM-C

Comco-PET

Comco-PEEK

Comco-PTFE / TF

Comco-PVDF

Comco PA 6.6

Comco PA 12 Cast

Comco-PE

Comco-Premium PP / PP-H

Comco-PVC-U

Comco-PC

Comco-ABS

Comco-PEI

PLAVIS™ Polyimide

Comco-PA 6 C

Polyamide 6 cast (PA 6/c) is a universal material for mechanical engineering applications. It features high mechanical strength combined with sufficient toughness and very good machinability. Its properties can be optimized for specific applications by adding other materials. The casting process allows for a wide range of shapes.

Material at a glance:

Comco-POM-C

This semi-crystalline thermoplastic features good frictional properties and high dimensional stability. POM-C offers high mechanical load-bearing capacity paired with good machinability. For all customers requiring mechanically precise components and strict tolerance ranges, our POM-C is highly recommended. Thanks to its low moisture absorption, POM-C is suitable for components that must function underwater or in a wet environment – humidity does not change its properties. POM-C is also resistant to a wide range of organic solvents and chemicals.

Material at a glance:

Comco-PET

Alongside POM-C and PA6 casting, PET (or PET P) is one of the most widely-used technical plastics. Its excellent mechanical properties make it ideal for applications like precision mechanical components. PET offers high tensile strength and mechanical load-bearing capacity, stable hardness and good dimensional stability. Because of its low coefficient of friction, Comco PET is frequently used for components demanding high wear resistance such as wear parts, bearings, bushings, turntables or track rollers. PET is also suitable for applications in the food processing industry requiring high chemical resistance and low moisture absorption.

Material at a glance:

Comco-PEEK

PEEK offers excellent mechanical strength, high chemical and hydrolysis resistance as well as high radiation and steam resistance. The continuous operating temperature of PEEK is about 250 °C. Thanks to its excellent thermal properties, PEEK is suitable for applications at very high temperatures. Its physical properties remain unaffected by the external environment.

Material at a glance:

Comco-PTFE / TF

The plastic with the highest resistance to chemicals and extremely low adhesion, Teflon / PTFE is a soft sintered material with a low level of mechanical resistance. Its most important properties are: resistance to almost all chemicals, very high continuous service temperature, 260 °C flame retardance, low coefficient of friction, extremely low adhesion, low strength and hardness and high frictional wear.

Material at a glance:

Comco-PVDF

PVDF is a high-performance fluoropolymer known for its exceptional chemical resistance, mechanical properties, and thermal stability. Compared to other fluoropolymers, PVDF offers easier melt processing due to its relatively low melting point of around 338°F (170°C).

Material at a glance:

Comco PA 6.6

Compared to PA 6, PA 6.6 has a slightly higher surface hardness and rigidity, as well as reduced moisture absorption. Further positive features include increased wear and heat resistance, but it has a lower toughness compared to PA 6. One popular modification is the 30% glass fibre reinforcement. PA 6.6 GF 30 features increased dimensional stability, very high rigidity and even greater heat resistance compared to unreinforced versions.

Material at a glance:

Comco PA 12 Cast

PA 12 C is a polyamide 12, produced using a monomer casting process. Due to the completely pressureless process, the material becomes highly crystalline and lowtension with a homogeneous, uniform structure throughout. The casting process allows for versatile design.

Material at a glance:

Comco-PE

Comco PE 1000 / PE-UHMW is a technical plastic used in many industrial fields to solve frictional and mechanical problems as well as material flow problems. The PE 1000 polyethylene product family is characterised by extreme wear resistance, high impact strength as well as excellent resistance to chemicals. These products have become well established in technical applications. It is an ultra-high molecular polyethylene, with a molecular weight of 4,000,000–9,000,000.

Other designations: PE-UHMW, RCH1000

Material at a glance:

Comco-Premium PP / PP-H

This product family is characterised by good hardness, rigiditiy and strength as well as their excellent resistance to chemicals. The materials have proven ideal for technical applications.

Material at a glance:

Comco-PVC-U

This plasticiserfree PVC features excellent chemical resistance and good workability. Thanks to its good electrical insulating properties, high resistance to acids, alkalines and saline solutions and easy processing, PVC has proven itself in the chemical industry. It is well established as a common material in container and plant construction, the electrical industry and the construction industry. Our PVC is free of DOTE, lead, cadmium, CFC, silicone, PCB, bisphenol A, plasticisers and heavy metals.

Material at a glance:

Comco-PC

We supply a wide range of technical polycarbonate products. PC is a transparent amorphous thermoplastic material, which has high impact resistance and high dimensional stability. Based on its excellent electrical properties combined with high resistance to solvents, PC is suitable for a wide range of applications in the electronics and electrical industry. Thanks to our unique tempering process, the PCP sheets and round bars are 100% deenergised and offer excellent machinability and dimensional stability.

Material at a glance:

Comco-ABS

This material offers ideal properties required for the production of prototype designs. Its residual stress is completely eliminated by the unique tempering process, which also results in excellent machinability and dimensional stability. ABS sheets are easy to process.

Material at a glance:

Comco-PEI

This semi-transparent amorphous thermoplastic offers excellent steam and water vapour properties, heat resistance and extraordinary dielectric properties. Its constant operating temperature is about 170 °C. PEI is ideal for applications that require reliable resilience and stability at high temperatures.

Material at a glance:

PLAVIS™ Polyimide

We use this ultra-high-performance plastic based on polyimide to manufacture semifinished and finished parts. PLAVIS™ is characterised by a complex property profile with many outstanding individual qualities – which places it and is thus at the top of our range of plastic materials. It fulfils the most demanding tasks in all areas of industrial electronics, aerospace engineering, transport and the machinery and heavy machinery industries, semiconductor, solar system and flat-screen manufacturing. PLAVIS™ is comparable with Vespel and can be used wherever something must be sealed safely, to minimise wear and friction, to resist high temperatures and harsh operating conditions as well as to save weight.

Material at a glance: